Standard Machine, LLC. has been in business since 1969 providing world-class large part machining services to customers in many industries.

Since then, a strong team of expert machinists, continuous investment in the latest technology equipment, and consistent performance have driven us along a path of steady growth. All of our projects are carefully planned and monitored, and we work 24 hrs/day, 5 days a week to ensure top quality results on specification, on time, and on budget.

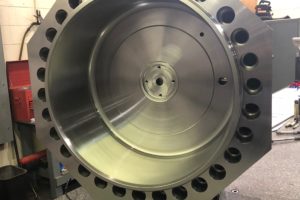

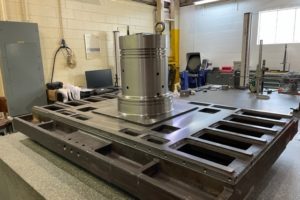

We are capable of machining parts measuring up to 180″ x 90″ on our CNC controlled equipment and up to 336″ x 110″ on manual drive machinery. We also have large CNC turning capabilities up to 90″ in diameter. Our state-of-the-art facility is equipped with high bay heavy lifting equipment capable of moving components weighing up to 30,000 lbs.

All mills are equipped with automatic tool changers to speed both simple and complex machining processes. We are expert at working with all types of materials, including iron, aluminum, titanium, as well as hardened and difficult to machine alloys. Tolerances as close as ±.0005” are easily achieved, and all inspections are conducted using the most precise measuring equipment available today.

Our leading-edge large part machining capabilities consistently meet a broad array of customer challenges. We machine precise parts for many different industries: Oil and Gas Equipment, Housings for High Speed Can Making Machines, Fluid Ends for Fracking, Large Aircraft Forgings, and Steel Mill Equipment just to name some of the industries we serve.

The parts we produce are machined from large fabrications, plates, castings, and forgings. Our facility is ISO compliant and we are able to adhere to and relevant industry standards.

For more information on our large part machining services, contact us today.

Large Part Machining Capabilities

- Machining Processes

-

Milling

Boring

Drilling

Turning

Tapping

- Machinery Axis

-

3

4

- Equipment Capabilities

-

CNC Control Capabilities

Horizontal Boring Mills

Vertical Boring Mill

Planer Mill

Automatic Tool Changers

- Materials

-

Steel

Cast / Gray Iron

Aluminum

Stainless Steel

Copper

Titanium

Tool Steel

Inconel

Monel

Hardox

Hastelloy

- CNC Length

-

Up to 180″

- CNC Width

-

Up to 90″

- Manual Length

-

Up to 336″

- Manual Width

-

Up to 110″

- Turning Swing

-

Up to 90″

- Lifting Capacity

-

Up to 30,000 lbs.

- Tolerance (+/-)

-

±.0005″

- Inspection

-

14′ x 8′ x 30″ Granite Surface Plate

96″ Ferro Arm Coordinate Measuring Machine (CMM)

Digital Height Gauges

- Testing

-

Hardness

Ultrasonic

Mag Particle

Dye Penetrant

- Documentation

-

Process Plan

First Article Deviation Request, Cause and Corrective Action

- Additional Capabilities

-

Fabricating

Blanchard Grinding

Surface Grinding

- Production Volume

-

One Piece to Production Quantities

Additional Information

- Industry Focus

-

Power Generation

Aerospace / Aircraft

Mining

Plastic Injection Molding

Gas Compression

Machine Tool

Steel Mill

- Intended Application

-

Press Machinery

Foundry Equipment Machinery

Bottling Equipment

Fabrications

Castings

Forgings

Plates

Magnet Cores

Fracking Components

Fluid Ends

Gear Housings

Platens

Bolsters

- Industry Standards

-

ISO Compliant

QS Compliant

MIL-I-45208

National Tooling and Machine Association (NTMA)

- File Formats

-

SURFCAM

DXF

IGES

PDF

TIF

DWG