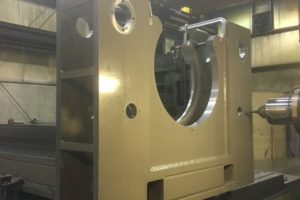

Specializing in large component manufacturing, Standard Machine, Inc. machines all parts using advanced CNC technology and carefully measures them to guarantee the highest quality precision.

We produced the Base and all of the associated components turn-key. It was a new design. Per the request of our customer, we consulted with their engineering group to help ensure that the parts could be produced in an efficient manner. Once the design was complete we purchased all of the materials.

This included all of the steel parts flame cut to shape. Many of the items were pre-machined for optimal fit-up for the Base Weldment. The other components were precision ground and then machined to the precise requirements of each separate part.

After all of the parts were machined complete each critical dimension was inspected with our CMM and other required gauges. The last step was to assemble the components onto the base before the final shipment.

- Project Name & Description

-

De- Twister Frame

- Equipment Used to Manufacture Part

-

Precision Grinding Machines, Large Vertical Planer Mill, and Precision CNC Horizontal Boring Mills

- Overall Part Dimensions

-

53” x 80” x 120”

Total Weight #28,500 LBS

- Tightest Tolerances

-

± .0005

- Material Used

-

Steel

- Surface finish

-

32 micro

- Industry for Use

-

Nuclear Power

- In Process Testing/Inspection Performed

-

Dimensional Inspection. Component Assembly Checks

- Volume

-

1

- Delivery/Turnaround Time

-

14 Weeks

- Delivery Location

-

Lynchburg, Virginia

- Standards Met

-

Customer Specifications